Cannabis cultivators maintain a fascinating role in the cannabis supply chain. Most downstream operations depend on strong cultivation partners. In 2020, growers faced a series of changes and supply chain issues that illuminate the value of data to the success of operators in the medical and recreational legal cannabis industry. From retailers, to manufacturers and distributors, the cannabis supply chain’s raw material is the flower that cultivators produce.

Data is abundant on the farm, existing in various forms for use by cultivation operations and their stakeholders. Visibility and transparency into these statistics and data sets will surely be essential for cannabis supply chains in 2021. Keep reading for a deep dive into cultivation data and the impact it can have across the supply chain.

What is the cannabis supply chain?

The cannabis supply chain is the process of getting cannabis from its raw materials to the consumer. The entire production and distribution system required for cannabis is called a “supply chain”. It includes cultivation, manufacturing, packaging and labeling, warehousing, logistics, retailing, and customer services.

Why Supply Chain Management is important

The lifeline of all society’s critical supplies is supply chain management (SCM). Supply chain management is an integrated and holistic approach to management that meets the demands of both producers and customers. Supply chains are only efficient if operations across various locations are working together and communicating in coordination.

Many cultivators make the mistake of thinking that when their cannabis product arrives at a distributor, that it’s the end of their supply chain. But because cultivators, like every other business in the chain, rely on product getting to the consumer quickly and while still fresh, strong relationships with distributors are more important than ever. Make distributor partnerships a crucial part of your supply chain management strategy.

Cultivators’ Role in Cannabis Supply Chain Logistics

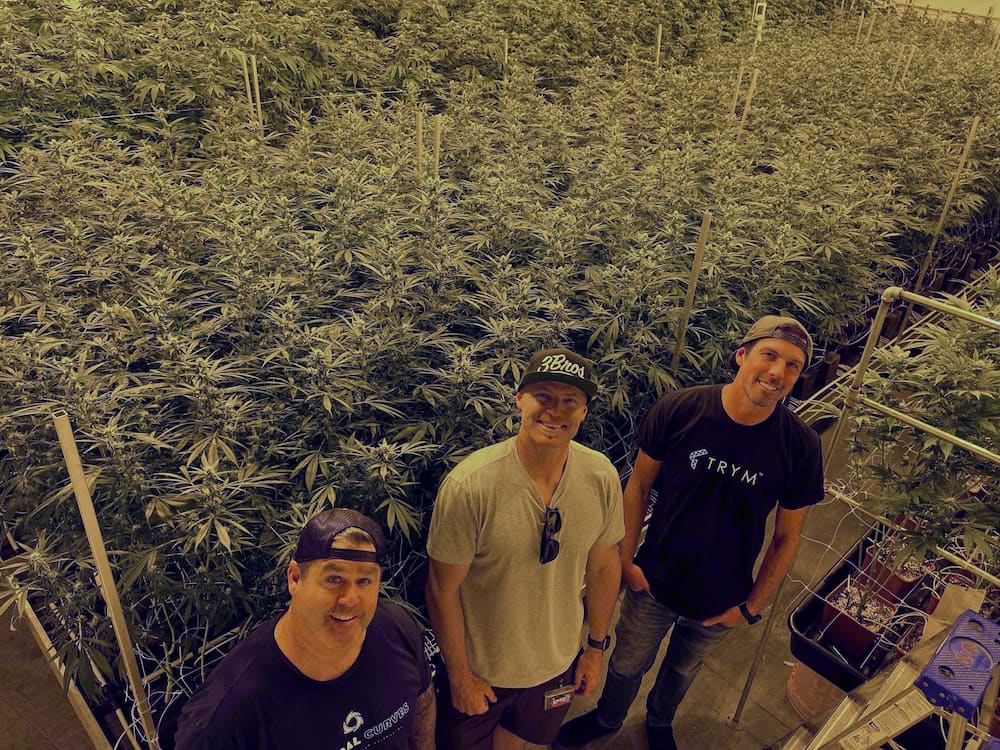

Cannabis cultivators play an integral role in ensuring that downstream operations have enough cannabis product to sell. Cultivators provide the raw material and are responsible for its cultivation, harvesting, storage, and processing. The cannabis supply chain logistics are complex and diverse. While federal cannabis regulations limit doing business within state lines, the network of cannabis producers, manufacturers, retailers and brokers is vast. There is no marijuana supply chain without growers. Seed to sale begins at the nursery or cultivation site.

Cultivators truly influence the whole supply chain, and yet they are also greatly influenced by it. Specifically, cultivators listen to the cannabis market dynamics through retailer channels and are informed of evolving trends in demand. While cannabis consumers are referred to as the ‘end user’, they are also the source of data or feedback that moves back up the supply chain. It’s a two-way street when it comes to learning and optimizing operations and performance.

Cultivation operations are sometimes stand-alone businesses or they’re one part of a group of medical marijuana licenses that perform other functions in the supply chain like extraction, distribution and retail. These cannabis companies refer to themselves as vertically integrated.

Where Cannabis Flower Goes After Leaving the Farm

There are many variations of the cannabis cultivation business model. Some grows are a part of a vertically integrated business, some cultivate solely for wholesale markets, and others brand themselves and deliver their own cannabis products to retailers.

Some cannabis cultivators are growing for their own brand and packaging up their flower into pre-rolls and jars. They can self-distribute directly to a dispensary or work with distributors to gain better exposure to retailers across their state.

Other cannabis cultivators transfer their flower and/or trim to their manufacturing facility for processing. A large amount of flower and trim produced by cannabis cultivators enters the wholesale market where bulk units can pass many hands before being placed in packaging material or sent out for extraction.

There are many combinations of the above for farmers. For instance, one farmer might design and print packaging for all of his top cannabis flower for retail, while selling his small buds and trim to a broker who will then sell to a concentrate manufacturer or edibles maker.

The cannabis supply chain has many participants and brokers benefiting from the transfer of cannabis goods through the network. The relationships with others in the market drives a price-competitive marketplace. One key idea to consider is the value-add in the supply chain. On the one hand, a vertically integrated marijuana business can be thought of as a number of separate, distinct business. Extraction of concentrates from flower is a wholly different operation than cultivation of flower. Different licenses, different incorporations, etc.

However, if you consider the margin a marijuana grower receives from selling their marijuana to a wholesaler vs the increased margin from extracting and packaging both branded flower and vape pens, you’ll see the total margin and profit basis is higher. Now whether the costs, risks and effort are worth it, given the complexities of the various business types in the industry, is another matter.

Why Cannabis Cultivators’ Position in the Market is So Important

From the outside, the cannabis industry appears to be a gold rush. But at closer look, the startup costs and regulatory compliance requirements make it a difficult one to operate in, at profit. Vertically integrated operations are capital-intensive with a lot of risk and increased compliance responsibility.

Those trying to perform all functions in the supply chain may not perform at the same level as those focusing on just one segment, like cultivation. There are certainly exceptions to the rule, but it’s more likely that those focusing solely on cultivation will produce the best product.

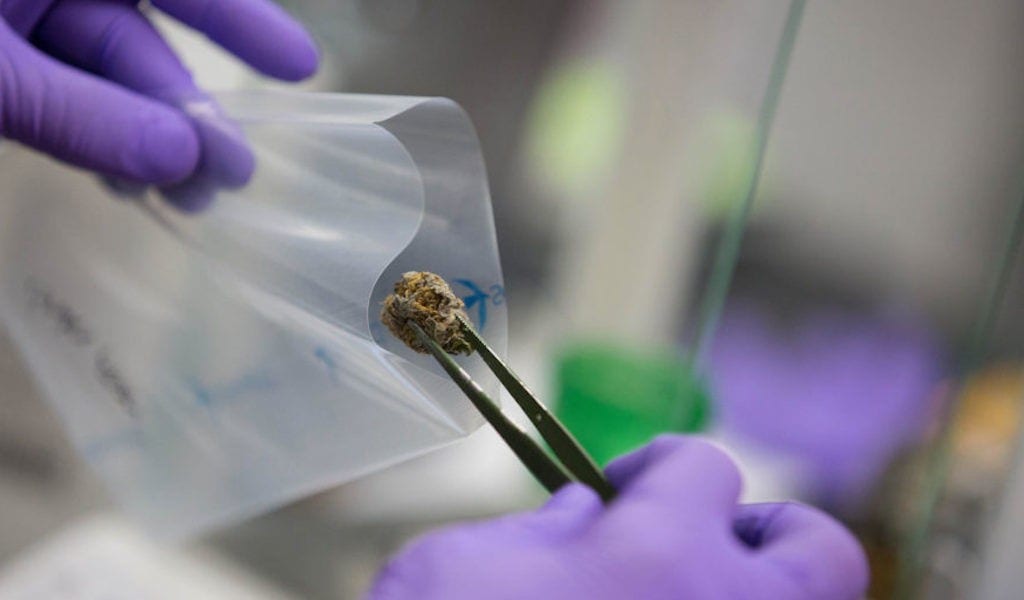

Quality of flower produced sets the tone for the whole supply chain. For extract manufacturers, the material going into their lab will determine their yields and efficiencies and ultimately profit margins. This is why a close relationship between operators is important. Some growers are even contracted out a year in advance to produce a specific strain that a concentrate brand requests.

Perhaps the biggest hurdle of all is passing the state’s required lab tests. Most states in North America have stringent acceptable levels of contaminants that make it difficult to pass. Those that are unable to pass sometimes have a chance at remediation, but ultimately if they fail the material must be destroyed, which greatly affects total medical marijuana supply in the market.

Discerning consumers are affected by these minor and major fluctuations in quality and price. And as the industry matures, cannabis consumers will continue to expect better quality at a lower price. The ability of cultivators to provide the supply chain with the highest quality flower and trim at efficient prices dictates the performance of the entire market.

What are the Biggest Challenges of the Cannabis Supply Chain?

Cannabis cultivators face a number of challenges that illuminate the importance of data to supply chain success. These challenges include:

– A vertically integrated cannabis company is a capital intensive enterprise with much risk and regulatory requirements

– Consolidation among manufacturers and distributors as businesses seek economies of scale amid declining margins

– Supplier shortages as demand outpaces supply

– The need to continually innovate cultivation techniques and product varieties

– Securing cannabis supply chain access and consistency

How can Cannabis Cultivators Close Gaps in the Supply Chain?

Cannabis cultivators have a number of options for filling gaps in the cannabis supply chain. These include:

– Partnering with upstream suppliers to find new sources of raw materials

– For example, linking up with extraction operations or manufacturers who are also struggling to meet demand and need additional flower

– Opening cultivation facilities in newer markets where there is less competition established.

– Increasing hybridization of marijuana strains to provide a wider range of marijuana products

For cannabis cultivators, data is essential for optimizing the supply chain. Data can be found in many forms on the farm but it will also need to be available throughout upstream operations – meaning that up-to-date information should flow seamlessly from cultivators to suppliers.

Changing Environment for Cannabis Cultivators

If it wasn’t hard enough for growers to operate profitably in the marijuana industry, nature throws curveballs that cultivators have to catch and adapt to. 2020 brought widespread fires across a great part of the United States. Many growers had to evacuate their farms close to harvest time and some lost their crops to raging wildfires. Many others’ flower was polluted by the smoke from the fires. Whether or not this affected passing lab tests is yet to be determined.

One thing cannabis growers know well is how to adapt to change. And 2020 has demanded this of them. Covid-19 has dominated the business landscape across all industries. Though federal cannabis legalization is yet to pass, cannabis was designated as ‘Essential’, meaning operators were allowed to continue working while many other businesses had to shut down.

Businesses had to adapt by decreasing the size of their crews and mandating mask wearing. For some it was a small impact but for others, working indoors, it affected their productivity and performance. Federal law will continue to evolve for the cannabis industry, restricting some supply chain movement, but overall increasing cannabis product production and reach to consumers.

Data Collected in Cultivation

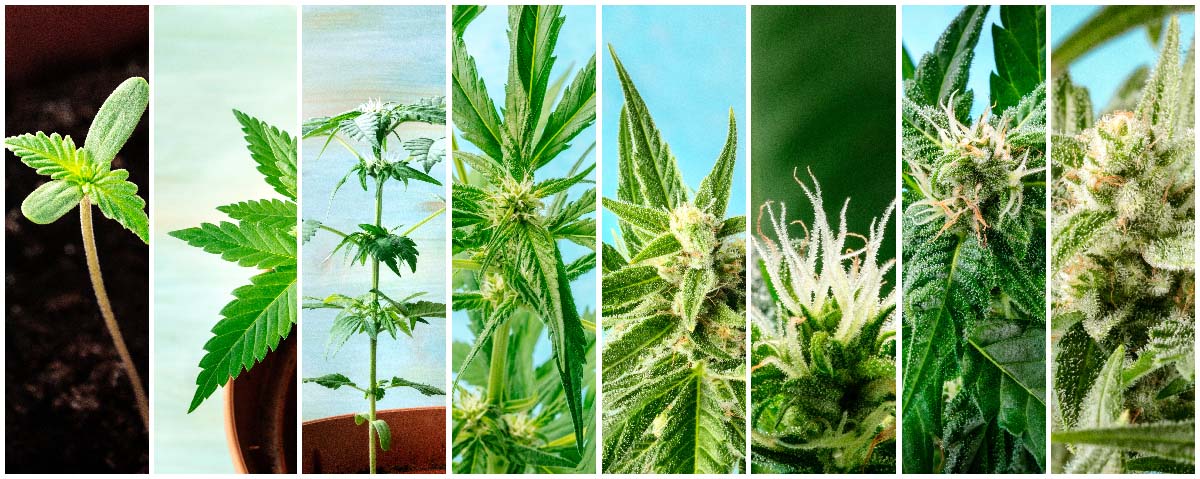

Cannabis cultivators track numerous variables to optimize production quality and yields. Traceability of the many variables manually and in isolated systems has previously been the standard method. But these days, commercial growers are adopting digital systems that provide instant access to data. Cannabis supply chain software collects and organizes important data and creates space for analysis. Studying the data can reveal areas of opportunity for streamlining and optimizing outcomes. Some common data points that are tracked and analyzed include:

– Physical data: lighting level and spectrum; soil type; pH fluctuations; nutritional requirements at various stages of growth; insect/pest presence; crop condition; yield estimates; and labor times on tasks, batches or strains.

– Environmental data: water quality (including run-off, leaching and residues); CO2 levels; temperature fluctuations; humidity levels; and energy balances for carbon footprint measurement.

– Commodity data: actual yields; qualitative attributes; trends in market demand for product types and genetics; and price analysis.

– Compliance Data: strains, plant type, cannabis plant count, product quantities, supply chain relationships, product packaged date.

When it comes to maintaining business during unprecedented environmental changes or simply refining processes on the farm, data is one of the best tools at any cultivators’ disposal. Visibility and transparency matter most to using data as a key resource. Using tools like cannabis supply chain software facilitates visibility and enables you to set and track KPIs.

Supply Data Visibility & Transparency: Why It Matters on the Farm

Most marijuana growers need tools for navigating complex supply chains and changing environments. One of the best resources at hand is data. As previously outlined, farms generate valuable data across operations. Creating visibility and transparency into those sets is essential for maintaining a cannabis company.

Data visibility is the ability for a business to easily access and work with its data regardless of its location. Transparency concerns stakeholders sharing data across their supply chain for internal and collaborative use.

A cannabis cultivator can better understand their farm operations and product movement from seed to sale with data visibility. When a grower and their partners create transparency, all stakeholders can plan supply strategically using shared data sets.

These practices help to ensure customer satisfaction, mainly through the monitoring of product quality, availability, and price. When data is either unused or siloed, it becomes challenging for farms to figure out how to optimize their harvests and measure the availability of their inventory downstream.

The types of data that are part of any cultivators’ operation are unique. Creating visibility and transparency into all the sets isn’t necessary. Instead, it’s better to strategize which data matters to whom and what shared metrics will make the most impact. Keep reading below for an approach to environmental and compliance data.

Cannabis supply chain software – critical features

At the basic level, cannabis supply chain software must perform certain functions.

- Built-in inventory management ensures that your stock levels are optimized

- Order and billing management

- Transportation and logistics tools ensure that materials are shipped efficiently and cost-effectively

- Supplier collaboration functions keep suppliers, customers and other key players in the loop.

- Deep visibility into the end-to-end functions and processes

Sometimes multiple software products come together to create a software stack that meets all business needs. For example Trym and LeafLogix are partnered to bring the best cultivation software available alongside a powerful seed to sale software that offers supply chain management functionality.

Get in touch if you’re interested in seeing how the two softwares work in tandem!

Leveraging Environmental & Compliance Data

Every grower is after greater yields. A never-ending puzzle to solve — how does one optimize their environmental conditions and inputs to produce the best quality at the highest yields? Space is constrained, so scaling up to produce more isn’t always an option.

At Trym, we help growers track their environmental conditions, a link that data to each batch of cannabis plants that they grow. This allows for analysis of each harvest and the opportunity to tweak and improve future harvest with hopes of increasing yields or optimizing for a certain cannabinoid profile.

Integrations with sensors like TrolMaster and Argus Controls allow for data collection of environmental conditions like temperature, humidity and Co2 in real time. Additional data points like VPD and soil moisture levels provide even more value and opportunity for crop optimization.

Compliance data is an excellent tool for leveraging inventory-related grow data both individually and in the context of supply chain relationships. Although METRC data isn’t immediately accessible through the platform, 3rd party options connect the data into an actionable resource.

Outspoke helps cultivators unlock and mobilize METRC inventory data. The platform brings compliance data into a dashboard with inventory-based insights and charts on supply levels, freshness, and product type. It’s also possible to share this data with other supply chain stakeholders.

When it comes to optimizing grow, scaling effectively, or refining supply chain relationships, environmental and compliance data are excellent metrics for creating impact.

METRC data is great for gaining an in-depth understanding of supply. Since the data is generally around measurements on product quantity, type, and quality, it’s suitable for sharing with downstream partners to enhance supply chain authentication and operation.

Tracking and analyzing environmental data is critical for consistent and optimal cannabis production. Tapping into climate and root zone data is the best way to understand what’s happening with your cannabis plants. Cannabis requires different conditions based on the stage of the plant’s life-cycle. And growers must be able to read the data and react to it to steer their cannabis plants towards success. Data is the answer and cultivators are becoming increasing savvy to advanced methods of data collection and analytics.

Data is the Future

With advancements in technology in both cannabis industry software and hardware, operators have access to an abundance of tools to optimize nearly every aspect of their businesses. More data is available than ever before and it can be an overwhelming task to track and understand it all. Choosing software to get better visibility into internal operations and consumer trends, will serve cannabis operators well and allow them to build successful and scalable businesses.

Co-authored by Ella Alpina and Matt Dell from Outspoke.io