Cannabis technology solutions are propelling this industry forward. Rapid innovation and development in hardware, software, and cultivation technologies are empowering growers and other commercial cannabis businesses to scale, produce higher quality cannabis products, stay competitive, and ultimately become more profitable. Let’s explore why cannabis technology innovations are so important to the future of the medical cannabis industry.

Why cannabis technology is important for your cultivation business

The importance of technology in business is critical to improve the competitive advantage and drive strategy and growth of your business. Technology and software we take for granted, like the internet, Zoom meetings, Google Drive, and more, are now the backbone of many businesses. For the cannabis industry, the role of technology will only increase in the future.

Some reasons why cannabis technology is important for your operation:

- Faster communication between team and management

- Increased efficiency of systems helps reduce costs and enables the business to grow rapidly

- Achieve more in less time and redirects employees to areas where they are really needed

Integration of cannabis technology

Cannabis tech startups offer something different for every department in a licensed business. A sales team uses software that’s very different from the cultivation team. But one thing all departments share, when it comes to technology, is the common goal to get organized, become more productive, and ultimately more profitable as a cannabis company. In the rapidly expanding cannabis industry, dialing in operations with the help of innovative technology, businesses can rapidly scale to capture market share nationally and globally.

The integration of cannabis tech means that your company’s systems and equipment work harmoniously. Centralizing all data helps leadership extract strategic insights and guide the company forward. What’s amazing about the cannabis industry is the amount of innovation, stemming from real, unmet needs.

From crop steering, to vertical farming, to cannabis genetics, key players in the marijuana industry are driving massive improvements and launching new products to help cultivators increase profitability and scale their businesses as legalization spreads.

Challenge to Implementing New Cannabis Technology

Implementing new technology can be disruptive to the business. The process of implementation requires strategy and planning, or you risk being in a worse position that when you started.

The biggest, most common challenge is team adoption of the new technology. Buy-in from the team members who will actually be using the technology is a requirement to the implementation’s success.

Management may envision an end point where the company operate seamlessly with the new tech, but the journey to get there is an after thought. In contrast, if from the very beginning, stakeholders and employees are engaged in learning, training and customizing technology to their needs, the end result is much more likely to be successful.

Cannabis Technology Innovations

Crop Steering

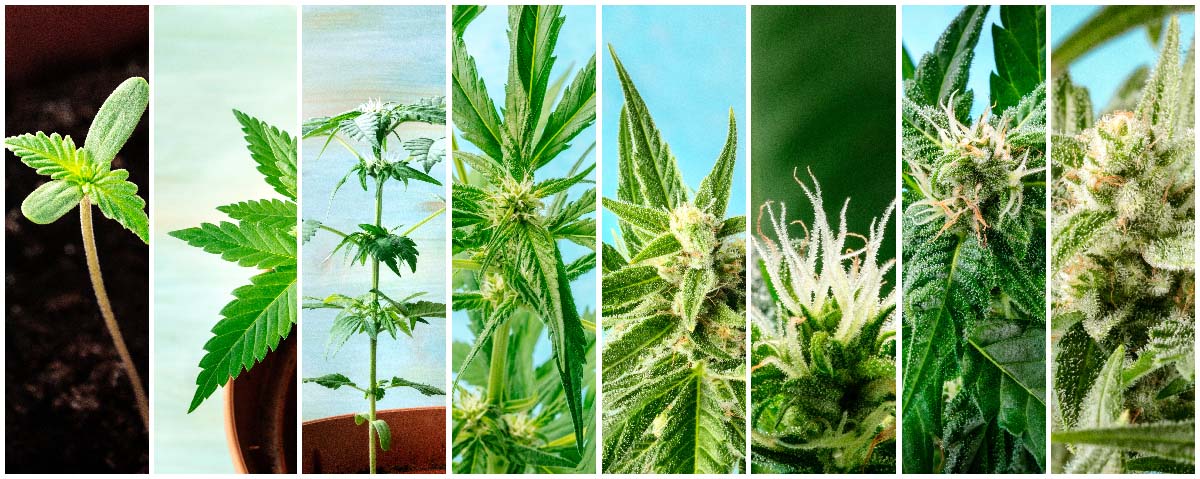

One of the biggest trends in indoor cultivation is crop steering. Marijuana plants have hormonal systems that regulate their growth in response to external stresses. Crop steering is essentially the exploitation of these hormonal responses, by manipulating a controlled environment to achieve a desired outcome – like higher yields. Cultivators can steer their plants through climate – such as increasing or decreasing humidity, or through irrigation, by increasing or decreasing the WC (water content) of the substrate.

When a plant is focused on production of leaves and stems, it is referred to as being in vegetative growth. On the other hand, when a plant’s focus is on developing cannabis flowers, it’s considered to be in generative growth. Precise ‘steering’ techniques encourage the plants to increase flower production at the optimal time in their growth cycle.

In general, the intent in commercial cannabis production is to maximize yield by optimizing the time plants spend in vegetative growth to ensure they produce only enough foliage and stems to support vigorous cannabis flower production.

Crop steering is accomplished with a system of sensors, controls, and tracking how climate and irrigation affect plant growth at each stage of the growth cycle. There are several awesome companies Trym integrates with in the cannabis space, like Trolmaster and Growlink.

Whether you’re growing cannabis in a greenhouse or indoors, lighting and CO2 regulation are critical for optimal plant growth. These hardware systems automate control of supplemental lighting, shade systems, and CO2 regulation. Sensors monitor environmental conditions, like soil and climate, and automate irrigation systems to feed the plants exactly what they need when they need it.

Marijuana technology solutions like software and hardware enable growers to create optimal growing conditions. In Trym, you can configure specific zones for monitoring and track all the sensor data like substrate temps, WC and EC. And most importantly, make observations in the app about your crop throughout its grow cycle. The ability to upload notes and photos, as well as log measurements in Trym, enables cultivators to quickly understand how their plants are responding to shifts in climate and feeding regiments.

If you’re interested in getting early access to these new features and leveling up your cannabis processes, book a demo with our team below. We’d love to show you the new new!

Key Players in Crop Steering

Growlink

An integrated environmental control system (ECS) is the best tool to make data-driven decisions in optimizing yields and production. Crop steering can bring a lot of precision and control to the grower’s cannabis operation, but only if the data is first centralized, accessible, and easily analyzed.

If you’re looking to begin crop steering, there are several hardware companies that offer climate and root zone sensors to collect the necessary environmental data. In our experience of working with many growers and the systems they’ve deployed within their facilities, we’ve grown to appreciate the engineering design of Growlink sensors.

Sensors and fertigation valves can connect directly to the Growlink controller. Our integration with their hardware enables you to visualize the environmental conditions in your facility and link them to the plants. Harvest analytics help you trace back to the conditions and feeding that resulted in the desired yields and quality of the final product. This is at the heart of crop steering. The power of centralized data allows you to test, track the results and change the strategy again in pursuit for perfection.

Growlink recently launched a new TDR (time-domain reflectometry) substrate sensor that tracks moisture and water content (WC). It’s critical for successful crop steering as it dictates when and how much to feed the plants, in each stage of their cycle.

The two most common soil moisture sensors are capacitance-based and TDR. The reason we’re big fans of Growlink’s root zone sensors is because the TDR technology is more accurate than capacitance technology, as found in Meter Group and Rika sensors. As salinity increases in the water, as is the case with nutrient feeding in marijuana grows, capacitance sensors accuracy decreases. Growlink’s TDR sensor accurately reports water content despite the increase in salinity.

For optimal crop steering results , having control over climate conditions as well as feeding schedules is critical. With Trym and Growlink, you can manage a cultivation team at one or many facilities and save hours combing through data and adjusting irrigation timers manually. Because in the end, your time is valuable. To execute crop steering correctly and produce the best results, cannabis technology is necessary to make adjustments at the right times in the growth cycle.

Vertical Farming

Vertical farming has really taken off in the cannabis industry in the last 5 years. As with most cannabis technology innovations, grow equipment has been developed for the cannabis industry’s unique needs. New product innovations and improvements are released each year.

The equipment and technology around vertical farming is composed of multi-level racking systems that hold custom-fitted grow trays. The racks are movable side to side and maximize the square footage of a grow space, both vertically and horizontally. Air ventilation systems have been developed for these setups to ensure even airflow through the vertical tiers where plants are located.

Vertical Farming demands an initial investment to purchase all the components, so it may not be accessible to smaller grows. But, those looking to save on energy costs long-term (LED lights are used due to close proximity to the plants) and maximize the yields produced in their facility, can make that investment up front to reap the benefits over the following years.

Key Players in Vertical Farming

Fluence by OSRAM

Fluence LED lights have been around for years. But back when they were a niche portion of the cannabis market, LED light efficiency and power did not compete with traditional HPS lighting. Growers grow for yields. Indoor cannabis cultivation is particularly expensive, as is the investment in lighting, so for many years, growers were not ready to switch to LEDs. But in the last 4-5 years, lighting technology has come a long way.

LED technology converts electrons into photons of light, directly through semiconducting materials. The continuous adoption of LED lighting has brought down costs significantly. Now, leading LED lighting manufacturers use more semiconducting materials to create better performing systems.

To give you an idea of how far LED technology has come, let’s compare Fluence’s SPYDR model from its initial launch to today’s SPYDR 2. In September 2012, when the product was released, it had an efficiency rating of 1.67 micromoles of photons per joule of electricity (µmol/J), and an output of 1,200 photosynthetic photon flux (PPF). Today, SPYDR 2 delivers 2.7 µmol/J and an output of 1700 PPF.

Today, the yields possible from growing under LEDs are two to three times greater than previously possible under HPS. In addition, their high-efficiency reduces operational costs by decreasing the amount of energy required to power the lights and the HVAC to cool the heat emitted. With the advent of vertical farming equipment, Fluence has developed lighting that snaps right into the grow racks without any need to modify or drill into the rack.

Vertical Air Solutions

With the rise in popularity of vertical farming, it quickly became apparent that cannabis tech companies needed to innovate to keep pace. One issue all indoor cultivators face is precise control of environmental conditions, like temperature, humidity, and CO2 levels. Growers using environmental sensors and control systems have the ability to dial in their climate to the exact conditions they know their plants prefer. Happy plants equal healthy yields and next to quality, higher yields are every grower’s top objective.

When cannabis cultivation facilities started adopting vertical rack systems to maximize their production, cultivators had to design their spaces to accommodate the install. A traditional air flow system, with ducting traversing the ceilings, in and out of the grow space, simply did not do the trick.

One of the earliest adopters, Fog City Farms, developed a custom air circulation system to address the problem of moving all the humid, stale air between the numerous vertical levels of plants. Microclimates form when plants transpire, so a circulation system that keeps consistent airflow throughout every part of the grow was critical to producing consistent results. There was no system quite like this on the cannabis market. Necessity is the mother of invention after all.

So Vertical Air Solutions (VAS) was born, and recently acquired by Pipp Horticulture, who produces vertical growing rack systems. VAS also officially patented their system, marking it as a true technological innovation in the marijuana industry.

Cannabis tech has always been developed out of a direct need. By growers for growers. At Trym, we developed our software by working closely with cultivators to understand their challenges and deliver smart solutions.. And we continue testing and innovating the user experience of our software in our own grow lab.

Genetic Engineering

The third emerging cannabis technology we’ll cover is gene editing, also referred to as Crispr-Cas9 or Crispr for short. Breeders have been crossing strains and selecting phenotypes for desirable traits for generations. With gene editing, years of breeding efforts are reduced to weeks to develop new strains that push the boundaries of the cannabis plant’s expression.

Crispr technology directly changes the plant’s DNA but doesn’t introduce foreign DNA into the mix, and therefore isn’t the same as GMO editing. Some people are against interfering with DNA and “playing God”. It’s hard to argue that humans haven’t been playing a guiding role in the plant’s evolution.

Cultivators have a very intimate relationship with the plant and have been shaping its genetic structure through intense cross-breeding initiatives. Some say the marijuana plant is the most hybridized and crossed plant in the world. So, consider Crispr as the high-tech version of breeding.

There are many traits that can be isolated and enhanced through gene editing, like:

- Disease resistance

- Pest resistance

- Climate tolerance

- Terpene and cannabinoid selection

- Increase trichomes

- CBD/THC ratio

- Biomass improvement

Key Players in Gene Engineering

CanBreed

One company that’s performing Crispr editing to develop seeds is CanBreed, founded in Israel and with cannabis operations in California. CanBreed will produce the first stable and uniform hybrid cannabis seeds, with 100% of the traits of their parent plants using genetic editing tools.

Many cultivators rely on clone production to maintain identical “true to type” offspring. But, there are drawbacks to growing from clones, like long-term degradation or genetic drift, high cost, and greater risk for pests/infections. Even the high-tech cloning methods like tissue cultures, do not prevent the aging of the mother plants. Over time, mother plants start showing age-related mutations. And eventually, cloning no longer produces genetically identical offspring.

CanBreed has licensed Crispr gene editing technology to develop stable seeds that produce uniform and consistent raw material for the cannabis and cbd industry. The company claims it has altered a gene in the cannabis plant to make the plant resistant to powdery mildew, one of the biggest threats to a cannabis crop. Their initial seed sales will feature this specific resistance and in the future, they’ll continue editing genes to enhance other desirable traits that can help farmers be more profitable in the industry.

The company recently purchased a 1.4 acre farm in Southern California and received their license to produce and breed hemp seeds. They expect to distribute 12.5 million hemp seeds in the first year and gradually ramp up to 50 million seeds per year.

Future Trends in Cannabis Technology

Genomic sequencing and cannabinoid biosynthesis are technologies to watch in the coming years. A cost-effective process for producing cannabinoids like THC, CBN, and CBD, is currently being developed and employed in labs around the world.

Another trend to watch for in cannabis cultivation technology is innovative e-commerce solutions for cultivators and other license types. Currently, e-commerce is mostly used to display products to consumers and make the purchasing experiencing seamless and quick. In the near future, cultivators will start to see more online services, like personal digital store fronts, to list their products wholesale or to consumers. Take for instance, the recently launched, Mendocino Cannabis Shop, where farmers have banned together to create their own online shop and a delivery company handles the last mile deliveries.

Working with Cannabis Tech Companies to Scale Your Business

Now that we’ve reviewed some of the leading innovations and cannabis brands in the industry, you may feel encouraged to look into implementing high tech equipment or software to power your cannabis cultivation business.

Here are some tips for implementing new cannabis tech:

- Select technologies that directly address your company’s growing pains

- Delegate a team of stakeholders that will be managing and benefiting from the new technology

- Test out the cannabis tech on a small portion of your operation to work out the kinks and gain buy-in from the team

- Train your employees to use the new hardware or software

- Implement it company-wide while tracking performance and fine-tuning along the way to ensure you get the most value from it

And if you are in the market for any software for your cannabis company, be sure to check out our guide to selecting cannabis software as well as the free tool we created to help you analyze and decide between the available choices out there.