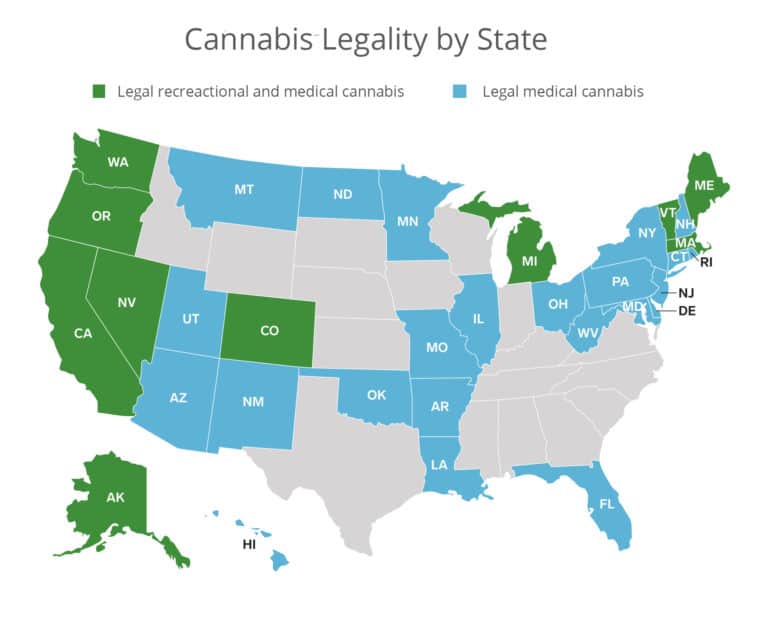

In 2018, Americans continued to use their voting power to express support for cannabis across the nation. Michigan became the 10th state to legalize recreational use, while Utah and Missouri became the 30th and 31st states to legalize medical cannabis. Millions of Americans now have access to legal cannabis and they’re loving it – lots of it. The medical market is poised to grow from $10 billion in 2018 to nearly $26 billion by 2025. Meanwhile, sales within adult-use markets are projected to double from 22 percent in 2018 to 44 percent in 2025.1 This is putting pressure on cannabis cultivators to scale effectively to meet demand and continuously innovate in order to compete successfully against current players, new entrants and established brands from other markets that all want to join the “green rush.”

Cannabis growers can up the ante and remain competitive as the landscape changes around them by leveraging data analytics to make strategic improvements to their operation.

Ditch the whiteboards

Replace them with technology and industry-specific solutions that can optimize cannabis farm operations through automation. Let’s face it, the cannabis industry isn’t the most sophisticated when it comes to data collection and analysis. Most growers are still tracking data manually via whiteboard, transcribing that data into notebooks and then at some point – maybe – it makes its way into Excel, where it sits until someone tries to make sense of it.

When you automate data collection you always have current information about your business, your crop, and your team. This also provides valuable historical data that, when analyzed, can provide insights into what aspects of your business could be improved.

Use software for team and task management

Growing quality cannabis requires substantial time investment and as cultivation operations scale, teamwork is paramount. The result is that labor comprises nearly half of cannabis production costs.2 There is great opportunity to reduce costs by making simple improvements to daily operations. Upgrading communication tools and using software to automate task management keeps employees productive and operations on track.

Software tools also allow you to derive insights with respect to team performance and labor expenses. This can be used to substantiate investments into your business, such as identifying the ROI of upgrading to an automated watering system by determining how much time your team spends on watering tasks each month. It can also be used to compare employee productivity and efficiency, allowing you to make strategic HR decisions, such as identifying employees that need additional training.

Know your key performance indicators

You’d be surprised what some simple data analytics can reveal. Measuring even basic key performance indicators (KPIs) such as batch data, productivity data, environmental conditions and operational expenses tells you a story of what’s happening with your business and how to improve it. Tracking and analyzing data related to KPIs allows you to make informed decisions to recreate your most productive batches, reduce operational costs, and improve your bottom line.

Cannabis farmers are on the precipice of a new frontier and efficiency has become an essential focus. Through continuous data tracking and analysis, cultivators can reduce costs, find inefficiencies, consistently deliver quality product, and increase their competitive advantage. With the green rush on full throttle, only growers who think strategically and continuously innovate will make it to the finish line.