About DeTerra

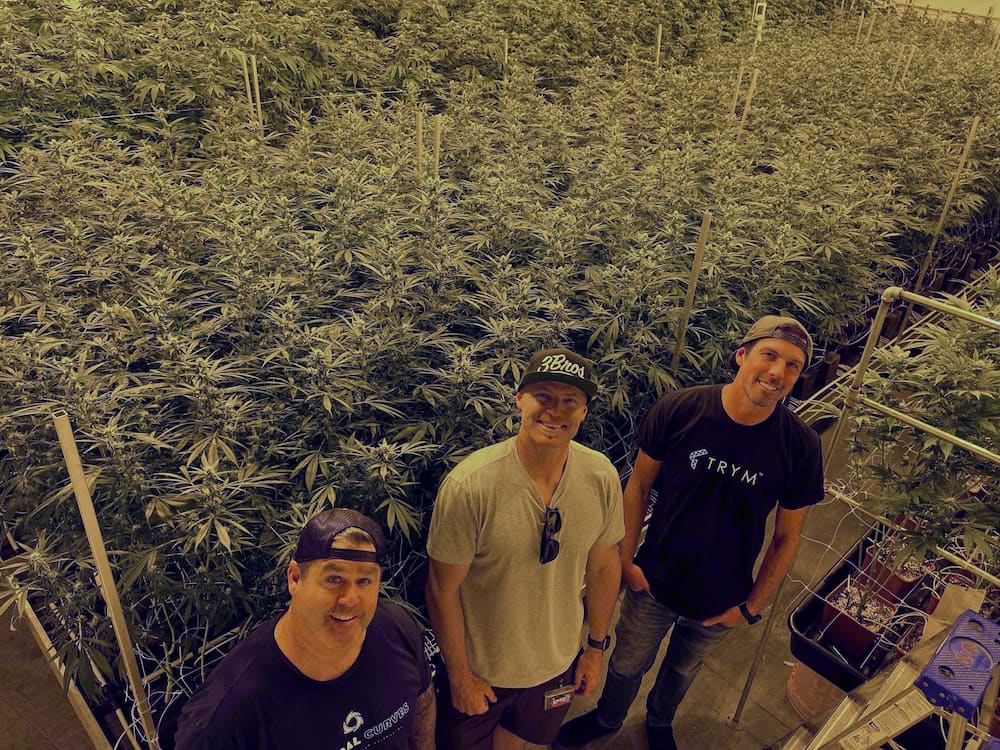

Born from the Green Rush, DeTerra is a relatively young brand in Oregon’s mature cannabis market. Mike, the company’s founder, spent years in search of an adept grower, seeking the promise of unmatched yields and quality. But they all fell short.

DeTerra had an ace up its sleeve: a penchant for securing top-tier genetics. Mike’s knack for introducing fresh and unique strains keeps DeTerra one step ahead. However, he still lacked a strong team lead who could level up the company and achieve great yields, consistently.

Enter Kyle Thorne

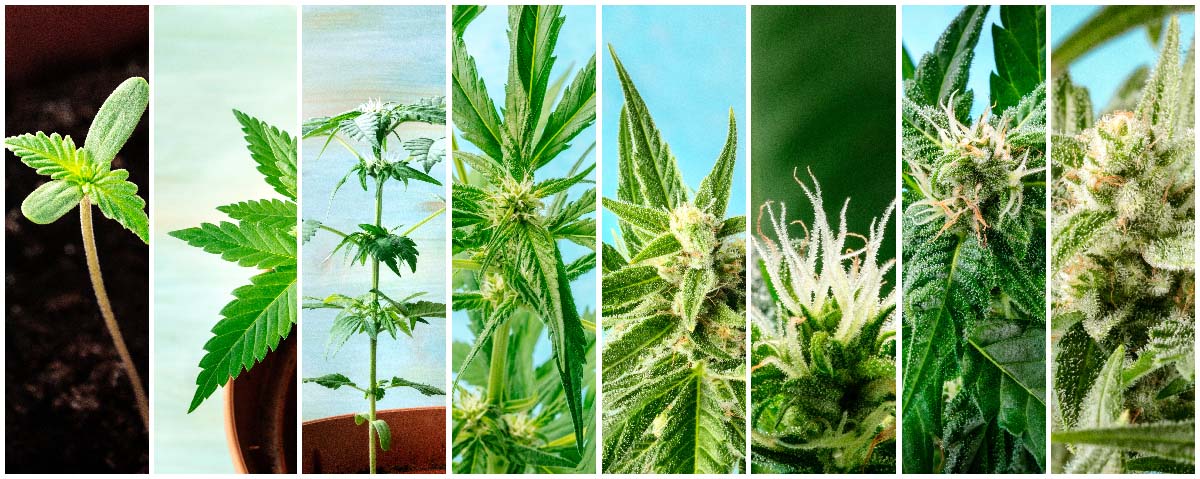

Kyle, stepping in as the cultivation manager, found DeTerra rooted in traditional methods: hand watering, no substrate monitoring, and basic hand meters for environmental checks. The lack of a structured approach and dwindling yields threatened the facility’s future. Kyle’s mission was clear: modernize and optimize.

The biggest challenges were low yields and no tasking system – the old grower just winged it every day. Knowing that he needed the right tools to transform the old-school operation, he set out to find the technology to help him achieve big results.

With some background knowledge in crop steering, Kyle wanted to invest in substrate sensors to implement ‘precision irrigation’ – one of the biggest contributors to DeTerra more than doubling their yields recently.

The Trym Difference

DeTerra experienced the transformation they were after. Their average yield skyrocketed from 1.4 lbs per light in 2022 to an impressive 3lb per light in their recent harvest.

As highlighted in the video, Kyle emphasizes:

“Trym bridges the gap, making facilities profitable. In a competitive market, you keep your facility alive by getting really good, consistent yields. And that’s not possible for me without Trym.”

The All-In-One Software Advantage

Trym’s edge lies in its holistic approach, with tools that streamline team management, crop steering, and compliance.

Trym vs. Aroya

While DeTerra initially reviewed Aroya before selecting Trym, Kyle found Trym’s offering more compelling. He said Aroya has an aesthetically pleasing UI and some unique features around precision irrigation. However, when it came to price and tasking functionalities, Trym won out.

Kyle elaborates, “The thing that made me choose Trym over the competition was the tasking functions. It’s very well-built and intuitive”

Crop Steering: The Game Changer

Kyle’s introduction to crop steering might have been rooted in curiosity, but its implementation at DeTerra was deliberate and strategic. Upon signing with Trym, DeTerra purchased 40 Teros-12 substrate sensors and 15 wireless climate sensors.

Kyle was intent on tracking multiple data points, including WC, EC, temperature, relative humidity, and VPD. The customizable condition graphs in the Trym dashboard empower Kyle to make informed decisions on what the plants need at any given time.

He’s also monitoring and making changes to irrigation volume, frequency, in-line EC, and doing the plant work to maximize the moves they’re making to the room and the pots.

Kyle says that while tracking environmental data isn’t anything new, the thought process on how to operate the rooms has been evolving a lot over the last few years. It’s hard to overstate the impact data can have on your yield and quality – and most importantly – repeatability.

“I’ll typically make one or two changes per run so I know for sure that what I’m doing is benefiting the end result. For instance, if I see one strain start fox tailing during bulking, the next run of that strain I’ll end my heavy vegetative steering a week or so sooner and see if that makes a difference.”

Kyle Thorne, DeTerra

Repeatability is the Goal

Kyle’s journey with DeTerra and Trym exemplifies the power of innovation and data-driven decision-making. With the right tools and expertise, transitioning from conventional methods to a cutting-edge operation is achievable.

As Kyle aptly puts it, “Trym makes achieving consistent, exceptional yields a reality. And for us at DeTerra, that’s made all the difference.”